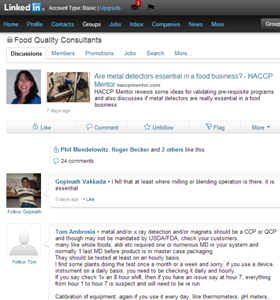

It looks like a topic that I touched on in Episode 7 has hit a conversation spot with many people who read or watched the recent HACCP Mentor update. The topic “Are metal detectors essential in food business?” has had so much feedback and comments on social media I wanted to share some other thoughts on the subject.

Feedback on “Are metal detectors essential in food business?” has essentially shown two trains of thought. In a nutshell, one camp says “YES” regardless of any background risk assessment with the other camp justifying “NO” if it has been justified through risk assessment. Not with standing any regulatory or customer requirements, I am a firm believer that metal detectors are not essential in a food business if it has been justified through a thorough and evidence-based risk assessment.

By this I mean, you can back up (with suitable evidence) allocated ratings for your likelihood and consequence of metal contamination in your products. I also believe that metal detectors are a reactive measure rather than proactive. Food businesses need to focus firstly on prevention – making sure that metal does not get in the food product in the first place. This can be achieved through the implementation of suitable pre-requisite programs around maintenance, GMP, foreign matter control, cleaning, approved supplier etc. If you would like to know more about a how to complete a hazard analysis correctly, check out this information on identifying CCPs.

These are just my views but I would also like to share comments that have come from others:

“Metal and/or x ray detection and/or magnets should be a CCP or QCP and though may not be mandated by USDA/FDA, check your customers. Many like whole foods, aldi etc required one or numerous MD in your system and normally 1 last MD before product is in master case packaging. They should be tested at least on an hourly basis. I find some plants doing the test once a month or a week and sorry, if you use a device, instrument on a daily basis, you need to be checking it daily and hourly. If you say check 1x an 8 hour shift, then if you have an issue say at hour 7, everything from hour 1 to hour 7 is suspect and will need to be re run.”

Tom Ambrosia

“Essential if it is a customer requirement; advisable if the process involves equipment or operations likely to produce metal FBs (e.g. high speed cutting, slicing, dicing, etc.) or if the product has a history (complaints) of metal FB contamination. In my experience metal detectors are probably the least understood and mismanaged inspection tools in the food processing environment, which adversely affects their reliability. This should be taken into account when assessing the need for metal detectors, which should be based on risk and consider other, possibly cheaper, measures.”

Bob Bowman

“Metal Detection, like any other health risk in the Food Industry is installed following a thorough Risk Assessment. If it (Risk) is likely to occur then install the metal detector. The last thing you need is to expose your consumers to tasting your metal-fortified product.”

Cedric M. Hlongwa

“I consider that metal detectors are essential only when a proper risk analysis is performed and the final conclusion is that there isn’t other methodology to eliminate the risk.”

Cesar Chaparro

“My view is that a metal detector is a good means to identify the presence of unexpected metal objects/material in the food manufacturing process. This will protect quality and safety of the product dispatched. The process protects organisation name, brand and maintains the reputation. gives the customer a good confidence….

However, the identification of metal objectives in the process of the product manufactured will assist to revisit what caused this object to be present in the first instance. Problem Solving (PS) must be effectively carried out and the outcome of the PS must arrive with immediate, short and long term actions, which many organisation need to improve on. Very often a band-aid fixes are evident. The focus must be on prevention action for the safety of all.

In order to arrive to identify the potential root cause, decision process and conclusions play a vital role of the PS team e.g. should manufactured food until that stage be isolated/ thrown away etc. based on potential risks to consumers. This also puts a doubt of the processes e.g. what about the product that is already manufactured in the previous shift and/or sitting on shelf and/or ready to be dispatched and/or in WIP stage etc. – could be expensive process”

Wilson Fernandez

These are just a few of the comments that were received. Thanks to everyone who participated. If you would like to share your views leave a comment below this post.

Thank you so much for giving good information about metal detector system.